Project Details

- Scheme & Version: International 2010 Bespoke

- Stage: Interim

- Location: Shanghai, China

- Size: 25,000 m2

- Score & Rating: 60.59% Very good

- Certificate Number: BREEAM-0048-9807

Project Team

- Developer/ Client: Shanghai Yinhui Restate Development Co.Ltd

- NSO: BRE Global

- Assessor/ Auditor: EcoIntel Beijing Engineering Consultancy Limited

About the Project

Shanghai International Shipping Service Center’s (SISSC) development on the Huangpu River in Shanghai aims to set a new standard in China for green, low carbon, smart and highly efficient buildings. The development has pioneered the use of BREEAM, the world’s leading design and assessment method for sustainable buildings, in the Chinese market in order to achieve these aspirations. The development includes the first building in China to achieve BREEAM certification at both design and post construction stages. This office building, known as Building 17, is formed of twin towers comprising 13 floors (including 3 floors underground) and has a total floor area of approximately 25,000m2. It achieved a BREEAM ‘Very Good’ rating at the design stage assessment, and an ‘Excellent’ rating at the post construction stage assessment. This case study provides an overview of how BREEAM was used to increase the sustainability benefits and value of Building 17.

Why BREEAM?

The BREEAM principles and methodology align closely with the Chinese Government’s policy for green buildings, which promotes sustainability through the efficient use of energy, water, land and materials. Using BREEAM as a design tool, Building 17 has been designed and built to high sustainability performance levels that go beyond current Shanghai and Chinese standards and practices, and has involved the use of a number of state-of-the-art technologies, features and processes. Consequently, Building 17 has achieved the highly regarded BREEAM ‘Excellent’ rating at the post construction assessment stage, representing performance equivalent to that of the top 10% of new buildings internationally. The following points highlight some examples of where Building 17 has demonstrated best practice in terms of the BREEAM performance requirements and therefore exceeded current Chinese standards.

Energy Efficient Design

In terms of energy efficiency, Building 17 has achieved a BREEAM ‘Outstanding’ level of performance, as energy modelling has demonstrated significant improvement over the local building regulations in terms of the building’s energy demand, primary energy consumption and associated carbon dioxide emissions. This has been realised by the following design features and technologies:

- A highly insulated building fabric, including the use of low-e glass windows and curtain walls, aluminium anti-thermal bridge windows and inflatable ETFE atrium roof.

- A mixed-mode ventilation system, which maximises the use of natural ventilation during spring and autumn through the exploitation of local wind flows and the stack effect by taking advantage of the site’s relatively open riverside setting and prevailing wind directions.

- Connection to a highly efficient district heating and cooling system that is based on a river water source heat pump and ice storage.

- An energy efficient lighting system that maximises the use of daylight through the glass curtain walling and ETFE atrium roof, as well as incorporating sensors to control lighting throughout the building, LED lighting in stairwells and external areas, and light tubes in underground areas.

Healthy Indoor Environment

The specification of building materials with low emissions of formaldehyde and volatile organic compound (VOC) was a key aspect of the materials selection that was informed by BREEAM requirements. Post construction indoor air testing for formaldehyde and VOC was performed and the results complied with the internationally recognised best practice health guidelines specified in BREEAM. The building also met the BREEAM health and wellbeing requirements for visual comfort (daylighting, glare control, external views, and lighting levels and controls), thermal comfort (thermal modelling and temperature control) and acoustic performance (indoor noise levels and sound insulation), which all involve compliance with international standards and best practice.

Low Environmental Impact Materials

The specification of construction materials in Building 17 was informed through the use of a robust tool that assessed the life cycle environmental impact of the various building elements, in accordance with the BREEAM requirements for materials. This led to the specification of materials with a low environmental impact, including a specific focus on materials with a low embodied carbon1, which makes the building an exemplar low embodied carbon case study in China.

Water Efficient Design

In terms of water consumption, Building 17 has demonstrated a 73% improvement against the BREEAM baseline water consumption performance standard, which meets the minimum performance requirements for a BREEAM ‘Outstanding’ rating. This has been realised through the specification of water efficient appliances and fittings (e.g. waterless urinals, dual flush toilets, low flow taps) and connection to the site-wide rainwater and greywater storage system, which has been modelled to meet all of the building’s WC flushing water demand.

Construction Resource Efficiency

By following the BREEAM requirements for construction resource efficiency, the construction waste management plans and procedures implemented by the principal contractor for the project went significantly beyond current Chinese standards. These included setting up dedicated waste recycling locations across the site and all contractors monitoring their construction waste. The plans and procedures ensured that 95% of construction waste generated by the project was diverted from landfill, which ensured the project met the exemplary level BREEAM performance requirements for this issue.

Construction Management Improvements

Following the design stage assessment a number of management related issues were identified that could improve the BREEAM rating and construction process at low or zero cost. This led to the implementation of integrated design process principles (e.g. enhanced collaboration between the client, design team and contractor; a schedule of training for building occupants and facilities managers) and the commissioning of all building services. Such measures will help to ensure that the building’s operational performance is in accordance with the design expectations.

Savings and Payback

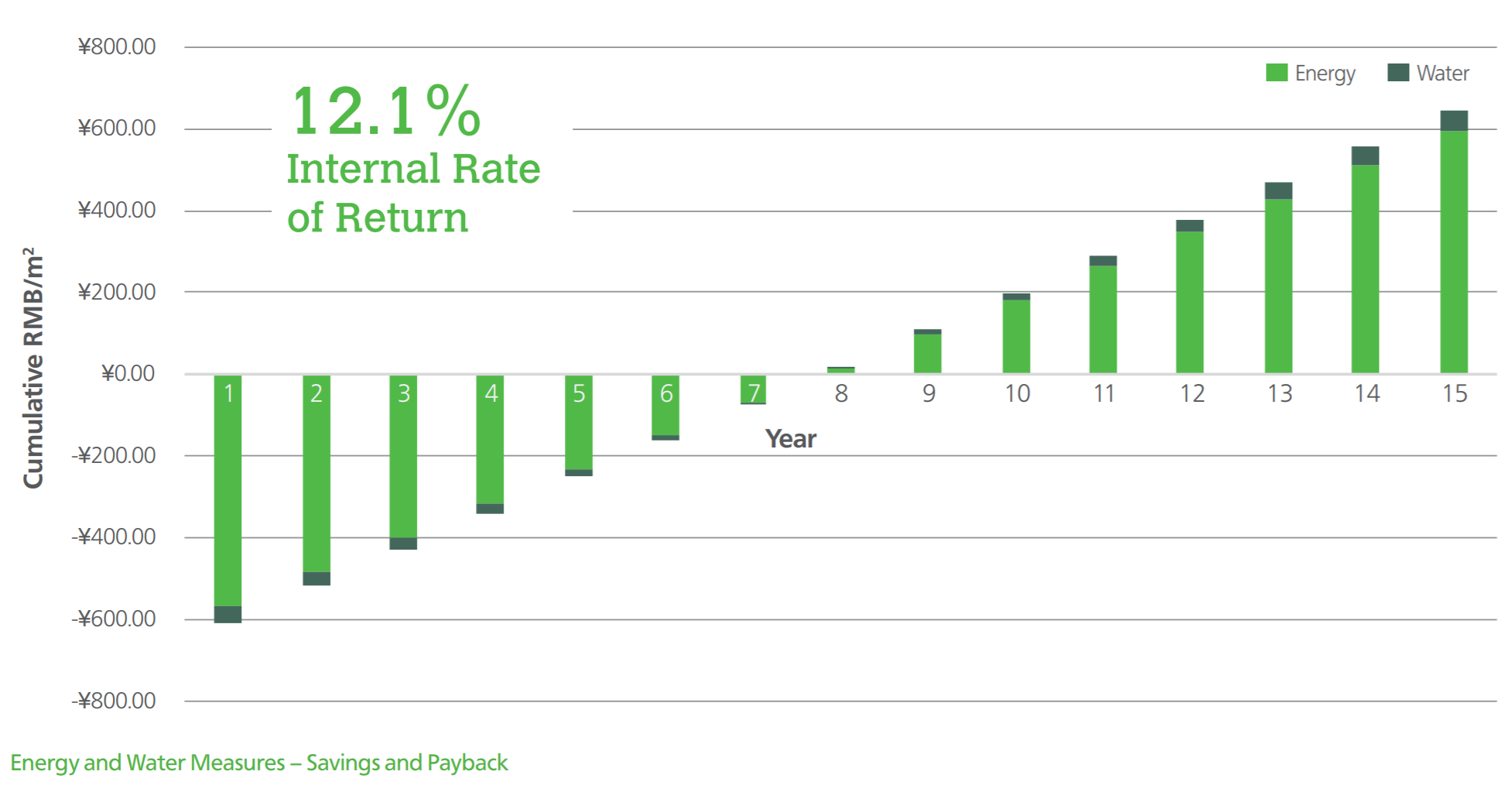

Achieving these higher levels of sustainability has incurred some additional capital costs compared to standard Chinese approaches. An analysis of the capital costs for the project has been performed, which has shown that the capital uplift for the project was less than 5%. Further analysis has shown that the additional capital cost of the energy efficiency features will payback in under 7 years (based on an electricity price of 1.05 CNY/kWh and a modelled 79 kWh/m2/year primary energy consumption saving compared to local building regulations requirements). In addition the water efficiency features will payback in approximately 6 years (based on water price of 5.0 CNY/m3 and a saving of 33,600 m3/year compared to the design standards of 50 litres per person per day for offices and 8 litres per m2 per day for businesses as stipulated in GB 50015-2003 ‘Code for design of building water supply and drainage’). Experience in other countries in implementing BREEAM has shown that uplifts in capital costs usually drop significantly with increased understanding and economies of scale.

Capital Cost Analysis

After the BREEAM post construction certificate was issued and the sale of Building 17 completed, Mr Binwu He (Managing Director, Executive Director and Executive Vice President of the Franshion Group Shanghai International Shipping Center) stated:

“BREEAM is the world’s leading sustainable building assessment method, and we found that it is suitable for use in China. Designing Building 17 in accordance with the BREEAM principles, not only saves land, water, energy and materials, and is environmentally friendly, but also meets world-class indoor environmental and health standards. As a result, the sale price of this building is significantly higher than similar non-BREEAM certified buildings in Shanghai.”

Outcomes

This case study has demonstrated that BREEAM can drive best practice sustainability performance in China for the design and construction of green buildings. The BREEAM “Excellent” rated Building 17 provides a best practice example for China in terms of meeting internationally recognised standards for energy, water and resource efficiency, low carbon materials and healthy indoor environments. BREEAM has also been used to improve construction management practices that will help to ensure that the building’s operational performance is in accordance with the design expectations. Achieving these enhanced levels of sustainability performance has only increased the project’s capital cost by about 5%. Additionally, the resulting savings on energy and water bills are projected to pay back the additional investment in energy and water efficient technologies in less than 7 years and approximately 6 years respectively. Building 17 has set a benchmark for green building projects in China using the BREEAM methodology, which will enable future projects in China to use BREEAM to push performance even further.